DryCon® Dry Disconnect Coupling

DryCon® Dry Disconnect Couplings has been developed in reaction to increasing safety-awareness during transport or loading of dangerous or sensitive media with the objective to make the operation of hose lines or fuel loaders safer, more economically efficient and more environmentally compatible.

With its user-friendly and simple handling, combined with best safety for man and environment, DryCon® Dry Disconnect Couplings allow quick connecting and disconnecting of filled hoses or fuel loaders without any significant loss of media.

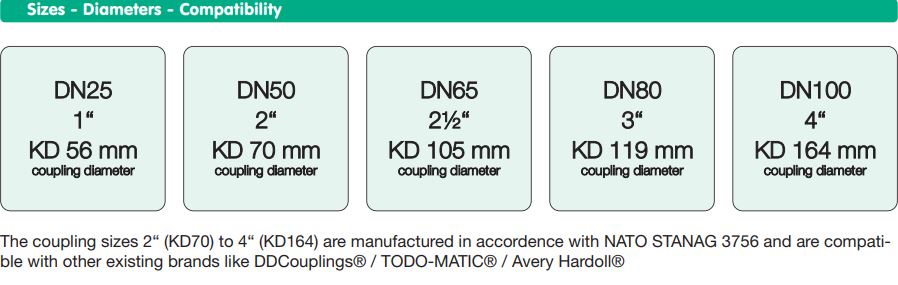

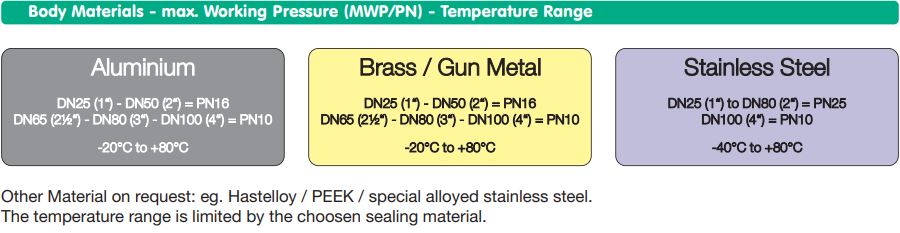

DryCon® Dry Disconnect Couplings are available in sizes DN25 (1”) to DN100 (4”) and can be used in almost any industrial application due to the diverse range of material combinations.

DryCon® Dry Disconnect Couplings are verifiably compatible with other manufacturers, such as TODO-MATIC® or DDCouplings® and thus the globally most widely distributed dry disconnect coupling principle.

A variety of leading companies from within of the chemical and petrochemical industry, offshore industry and pharmaceutical industry trust in the DryCon® Dry Disconnect Coupling system in the conveying of many different media.

Typical areas of use:

Loading and unloading of tank trucks or railtankers (RTC)

Fuel loader systems

Mixing systems (exchange manifolds)

Internal product transfer

Ship loading - “ship/ship”, “ship/shore”

Ship refuelling

Fuelling of locomotives

Filling/Bottling of paints and varnishes

Disposal of waste oils or toxic substances

Filling/Draining of IBC-containers

Internal distributor systems

Approvals - Certifications:

CE type examination and type approval according to 97/23/EG(EC) - Pressure Equipment Directive

CE type examination according to EN14432:2006 - GGVSEB / ADR 2013 / RID 3013

Conformity assessment procedure according to 94/9/EG(EC) - ATEX

Compliance with the CEFIC recommendation for the distribution of Ethylene-, Propyleneoxid, Acrylnitril

Compliance with the requirementsof the NATO STANAG 3756